What is Kanban? An Introduction to Kanban Methodology

Kanban is a way for teams and organizations to visualize their work, identify and eliminate bottlenecks and achieve dramatic operational improvements in terms of throughput and quality! Kanban is a method to gradually improve whatever you do – whether software development, IT/ Ops, Staffing, Recruitment, Marketing and Sales, Procurement – in fact, almost any business function can benefit from applying Kanban to bring about significant benefits such as reduced lead time, increased throughput and much higher quality of products or services delivered!

Kanban is a way for teams and organizations to visualize their work, identify and eliminate bottlenecks and achieve dramatic operational improvements in terms of throughput and quality! Kanban is a method to gradually improve whatever you do – whether software development, IT/ Ops, Staffing, Recruitment, Marketing and Sales, Procurement – in fact, almost any business function can benefit from applying Kanban to bring about significant benefits such as reduced lead time, increased throughput and much higher quality of products or services delivered!

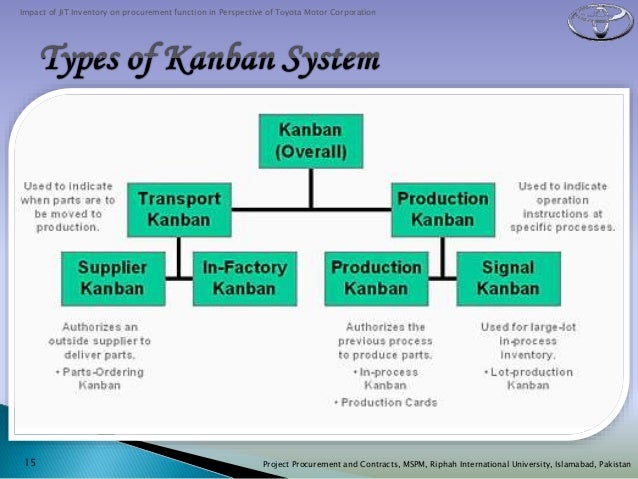

Kanban, also spelt kamban, is a Japanese term for “signboard” or “Billboard” that indicates “available capacity (to work)”. Kanban is a concept related to lean and just-in-time (JIT) production, where it is used as a scheduling system that tells you what to produce, when to produce it, and how much to produce.

Between the 1940s and 50s, Taiichi Ohno of Toyota applied the Kanban logic in their Toyota Production System (TPS) to support non-centralized “pull” production control. In the post-depression era of 1970s, Kanban was popularized in the manufacturing industry as a tool for Lean Manufacturing. Of late, many thought-leaders in various industries have found its applicability beyond the manufacturing industry as well.

In simplified terms, Kanban is a visual system for managing work moving through a process – the “value stream”. It is a system for visualizing work, reducing waste by limiting work in-progress, and maximizing customer value.

Application of Kanban in Software and IT

In the software and IT world, the definition of Kanban has undergone it’s own evolution and elaboration, especially over the last 2-3 years. The Kanban Method was defined and has been enhanced by David Anderson. Today, Kanban is considered as an agile management method for managing and improving service delivery (in both software/ IT and non-IT contexts) in a gradual, evolutionary manner. The 3 fundamental guiding principles of the Kanban Method are:

- Start with what you have now – that is your current process.

- Agree to pursue an evolutionary approach to change and improvement

- Respect the current roles and responsibilities of the team/ organization.

Based on these guiding principles, the Kanban Development Method describes the following five core kanban practices which were commonly observed in organizations which experienced success in using the Kanban method.

- Visualize the Work and the workflow that it follows

- Limit Work-In-Progress (WIP) using a virtual Kanban system

- Manage Flow

- Make Management Policies Explicit

- Use Models and the scientific method and Improve collaboratively

A Kanban software works on the target process, whether a software or IT process or a general business process, and helps to smooth the flow of work to maximize “throughput” and achieve high product quality. Kanban helps you make changes and improve your process. As such, Kanban often results in a new process that is worked out by the team or the organization itself in a collaborative and gradual manner. In the context of software and IT, Kanban helps teams to deliver software and services more smoothly, more frequently and at an optimized flow and throughput levels. A team that is currently using the Scrum method will be able to change its process to potentially move away from a batch/ time-boxed delivery method to a more continuous delivery model.

In summary, unlike many methodologies which bring about disruptive changes in an organization’s processes, Kanban is an evolutionary method that promotes gradual improvements to an organization’s processes. This makes implementing Kanban far easier than other approaches, making it an increasingly popular tool for managing any type of work, including Agile software development.

Kanban beyond Software and IT

Given its roots in manufacturing, Kanban has a natural fit in non-IT/ Software business processes as well, with tremendous benefits to the organizations wanting to become lean and to deliver high quality products and services. For a background on Lean/ Kanban in a more industrial context, please follow this link from Creative Safety Supply.

While medium and large product and services organizations, especially hi-tech manufacturing companies, have been implementing Lean/ 6-Sigma initiatives for several years, Kanban has the potential to enable all types of companies and business functions such as HR, Marketing, Sales, Procurement and so forth. Kanban is also being applied in traditional project management situations such as constructions and engineering projects. A wide variety of organizations – staffing companies, recruitment organizations, advertising agencies, insurance companies and many others are looking to Kanban for streamlining their operations, eliminating waste and dramatically improving throughput and quality.